Jeffersonian Design using Custom Design Manufactured Stone | Old Parkland, Dallas, TX | Specially Designed Columns, Egg-n-Dart Rope Design, Large Dentils, Profile | Project Specific Custom Molds, Product Batch Mixing, Manufacturing, Sequencing, Delivery, Installation Support

The technology and design expertise to develop custom molds enable flexibility to fabricate stone panels with an unparalleled range of complex shapes and design details.

VIDEO: Custom mold making for complex shapes, intricate design details, custom sizes:

PROJECT: SMU COMMONS

Custom molds made it possible to create large size custom stone panels with stringent tolerance requirements. Detailed engineering of anchoring connections played a crucial role in achieving a monolithic stone look for the facade veneer of the building.

Project: SMU Commons Building Facade | Architectural Stone Cladding, Veneer | Cast Stone, Precast Concrete, GFRC

Project: SMU Commons | Architectural Stone Cladding, Veneer Design | Custom Mold Making | Design and Technology

Architectural Stone Cladding | Cast Stone, Precast, GFRC

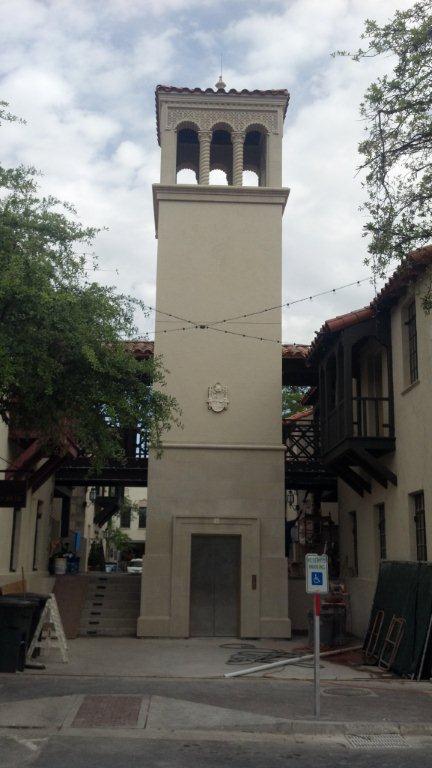

Columns with intricate design details at the top of the tower developed a signature highlight for the shopping center experience.

Clock tower connected with seventy-five years old shopping center area | columns at the top accentuate the design accent and shopping mall experience

Highland Park High Design Custom Columns

The design combined cast stone and GFRC (Glass Fiber Reinforced Concrete) product materials.

LEARN MORE >>

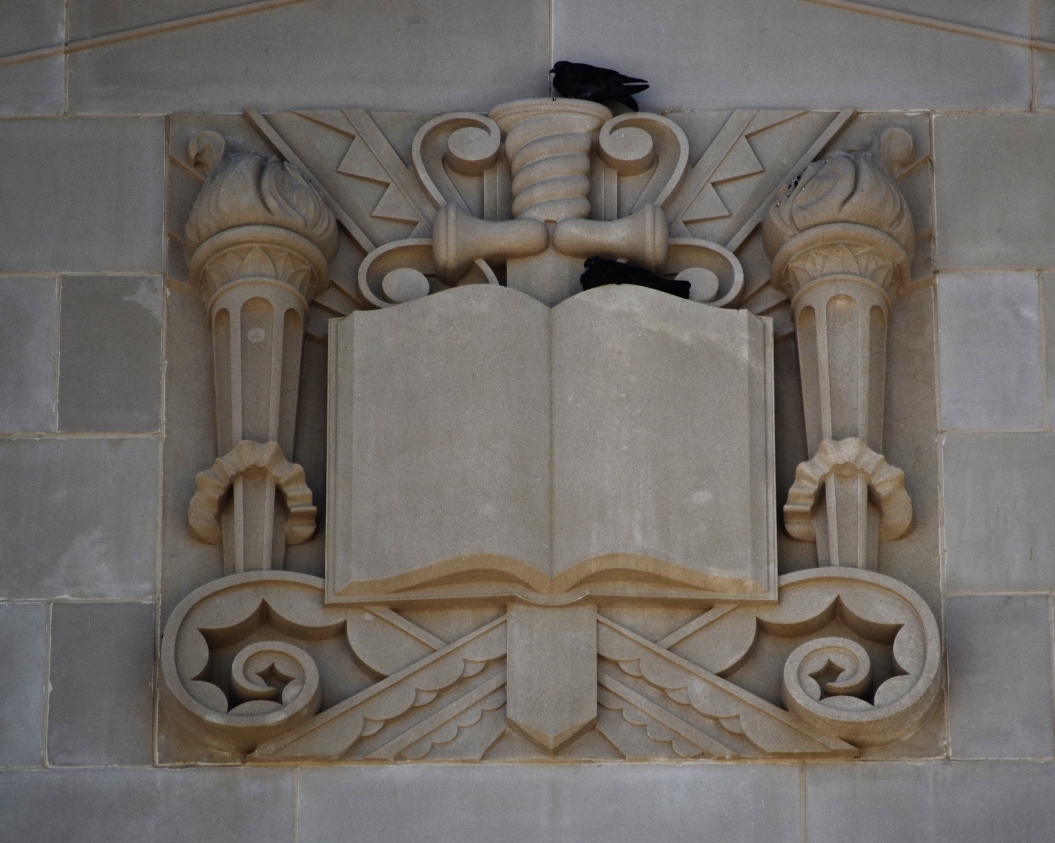

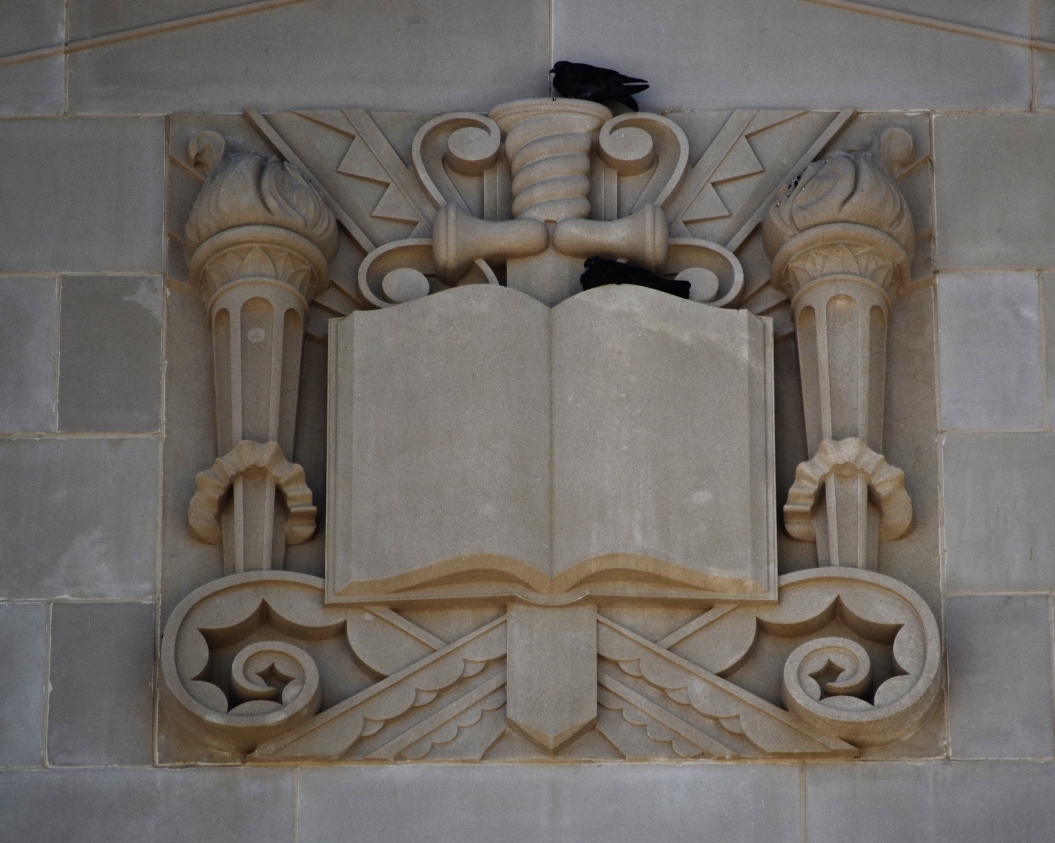

On The Westbrook Building, the cast stone was used in the overall design of the building to be reminiscent of the Art Deco structures located in many areas in Ft. Worth.

AAS Project: The Westbrook – Sundance Square West – Ft Worth, TX | Art Deco Design using Cast Stone | Custom Mold Design | Architect: Bennett Benner Pettit, Inc

Architectural Stone made the molds for the Art Deco designs from isometric sketches provided by the architect. In other words, the descriptions provided three sides, all in dimensional proportion, but none were shown as an actual shape with 90-degree corners.

The sketch was only a guide to making actual size molds. Artisan designers created molds for the Art Deco panels combining their design craftsmanship with extensive CAD drafting and also precision cutting using CNC machines.

The Westbrook Building at Sundance Square, Ft Worth, TX | Art Deco Design, Custom Design Elements using Cast Stone, GFRC | Architect: Bennett Benner Pettit, Inc

PROJECT CASE STUDY >>

PROJECT: High-End Design Element Using Custom Mold – Rockwall County Court House

The architect for this project had a vision for unique design elements on the exterior of the building. AAS team designed a highly intricate mold to create it in cast stone. The precise tolerance and detailed coordination with the construction team helped create the desired look with a smooth installation that completed on time.

Advanced Architectural Stone – AAS – Formerly Advanced Cast Stone | Rockwall County Courthouse | Cast Stone, Precast | Technology Allowed Complex Shapes and Desired Aesthetic Design | Brinkley Sargent Architects | DMG Masonry

This project consisted of 6 panels installed in the entry to the remodeled and enlarged football stadium at Texas Christian University. The panels were made using architectural precast and cast stone. The purpose of the panels and the project was to honor the founders of the University dating to 1895.

The architect for the project, HKS Architects, hired an artist to approve and render the murals. The AAS team transferred the original artwork to a rubber mold for casting. The panels represent the cultural icon at the heart and soul of Texas Christian University. It was critical that the panels could be seen within a few feet of the viewer. AAS team used its experience and technology to refine every detail within the mold so that panels accurately depict the original aesthetic appeal so critical to the project’s success.

The project won the 2014 APA (Architectural Precast Association) Craftsmanship Award.

Following is a composite image showing example panels.

AAS 2014 APA Award | TCU Relief Panels | Finish and Precision for Design Appeal | HKS Architects | General Contractor: Austin Commercial

AAS 2014 APA Award | TCU Relief Panels | Forming using Precise Molds, Design Experience | HKS Architects | General Contractor: Austin Commercial

Trahan Architects had a vision for emulating Cane river channels inside the Louisiana Sports Hall of Fame Museum. This required cast stone panels with complex shapes. The stone pieces were also huge. The project execution also demanded stringent tolerance requirements in the mold so that the stone would fit in seamlessly for a consistent look.

Advanced Architectural Stone (AAS – Formerly ACS) Team Supports Contractors, Builders, Masons – construction of LA Sports Hall of Fame Museum

LA Sports Hall of Fame | Large Size Precision Molds for Design That Had Highly Stringent Tolerance Requirements

LA Sports Hall of Fame | Cast Stone Realized Cane River Channels | Trahan Architects | CASE STUDY >>

LA State Museum Sports Hall of Fame | Trahan Architects | Cast Stone Veneer Developed using Complex Shaped, Large Cast Stone Pieces Fitting within Stringent Tolerance Requirements | LEARN MORE About Design, Manufacturing Process…

PROJECT CASE STUDY: LA SPORTS HALL OF FAME >>

The requirement was that the AAS stone would match the pre-existing terracotta stone.

714 Main St | Cast Stone for Building Exterior | Quality Experience, Desired Colors and Finish | Cost Effective Solution

The design had the Roman Heads depiction on the outside, which were authenticated and designed by artists. AAS team worked closely with the architect and artist to design and create the representations in cast stone that matched the original rendering of the artist precisely.

AAS Custom Mold Making | Roman Head Design in Cast Stone for 714 Main Street Building, Dallas, TX | Cast Stone Cladding

AAS Project: 714 Main Street | Unique Technology, Craftsmanship to Replicate design of Roman Heads | Product used Architectural Cast Stone

>See more on this project

AAS team helped create exterior fronts of the building that used cast stone and architectural precast extensively. The design used grape leaves build from the cast stone panels. The integration of the grape leaf design connects with the historical name of the city, and the local culture.

The AAS project team used custom molds to create highly intricate grape leaf design elements that are an accurate representation of the original design renderings.

AAS Cast Stone | Custom Mold Making | Grapevine Leaf Designed using Dry Cast System

Specialized Rubber Molds for Grape Leaf Design | Cast Stone Design for Grapevine Convention and Visitors Bureau

Grapevine Convention Center | High-End Leaf Design – Exterior Cladding | Cast Stone | APA Award of Excellence | ArchiTexas | J & E Masonry

AAS Cast Stone Project | Specific Color Contrast Requirements from the Architect of the Project ArchiTexas | Grapevine Convention & Visitors Bureau

> LEARN MORE: Creative Art Design Process for the Grapevine Leaf Design Elements

> See more on Grapevine Convention Center and Visitors Bureau Project.

Gilbert Christian High School is located in the city of Gilbert in the Scottsdale (AZ) area. The school exterior used extensive Architectural GFRC elements that were easy to integrate with the exterior thin brick veneer of the building. The column capitals have Corinthian style.

AAS Architectural GFRC Case Study | Gilbert Christian Case Study

AAS Architectural GFRC Case Study | Gilbert Christian High School | Custom Molds and Finish | Simplified Installation with Higher Elevations, Brick Veneer

See more about the Gilbert Christian High School project in the case study.

This is a new development added to the school campus.

The entryway of the building has a very high elevation breezeway. The cast stone and architectural precast panels required custom molds that enabled panels of such a big size that would fit together to create a seamless effect in the breezeway.

TCU Worth Hills Cast Study | Large Size Custom Shape Cast Stone Panels for Architectural Design

AAS (Formerly ACS) | Project: Texas Christian University (TCU) Worth Hills Campus, Entry Gate | Cast Stone, Architectural Precast

Large Size Custom Stone Panels Fit in for Monolithic Stone Look | Fabricated Stone Veneer, Cladding Design

The AAS team tapped into its extensive experience with the design of elaborate balustrade systems as well for this project. The dimensions and shape of balusters had specific requirements; custom molds were developed for this as well.