Architectural GFRC – Thin Concrete Panels for Exterior Cladding, Veneers, Columns

The architectural GFRC, Glass Fiber Reinforced Concrete, has a concrete front facing with options to match the look of virtually any other type of stone product. The back is sprayed with layers of glass fibers and concrete admixture to make it ¾” inch thick.

- Since the GFRC stone panels are hollow from inside, they are much lighter than other cast stone or natural stone products with very competitive strength to weight ratio.

- AAS has the technology and design expertise to custom fabricate the panels with an unparalleled range of complex shapes with stringent tolerance requirements.

- The GFRC products can have pre-engineered connections integrated at the time of manufacturing, simplifying the installation process.

- Customers have options to match the GFRC products with other stone products such as dry-cast stone, wet-pour precast concrete, limestone, terracotta, etc.

The GFRC products are as durable as other cast stone products, retaining the structural properties and the color and finish; this provides a significant design and cost advantage over other thin veneer panels.

Case Study: GFRC Design Process

Design assist, custom GFRC manufacturing, construction assist, installation support […]

St. Francis Church: Case Study

Combined GFRC, Dry Vibrant-tamp Cast Stone, Wet-pour Precast Concrete […]

GFRC Connections Simplify Installation

Pre-engineered GFRC connections simplify installation, open up design options […]

Architectural GFRC: Advantage, Process

Architectural GFRC | Technology, Engineering Manufacturing, Formability, Ease of Installation […]

Why GFRC? When Does It Make Sense?

GFRC Primer [Project Image Above: USC Ronald Tutor Center] […]

For Architects

AAS System to cater to architects’ design process, project specific custom fabrication […]

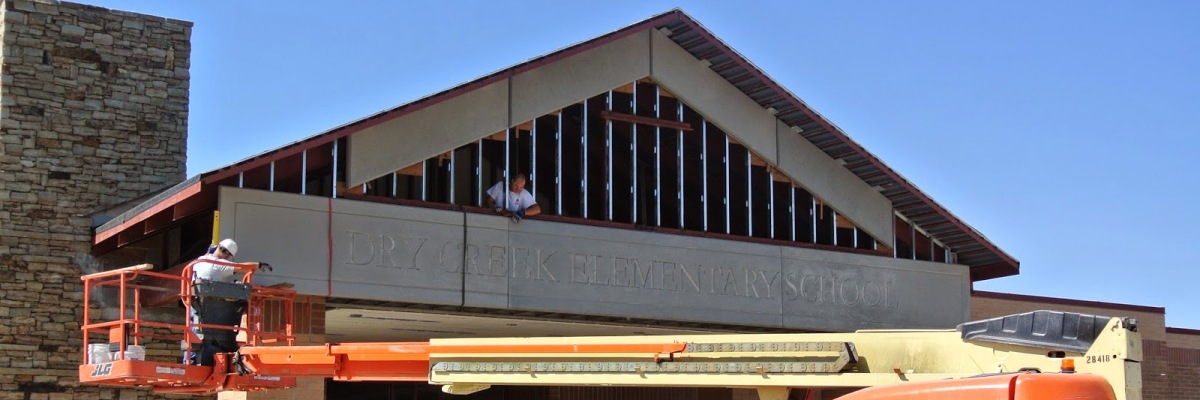

CASE STUDY: Dry Creek

Custom GFRC Panels at Higher Elevation of School Entry Way | Lighter Weight, Pre-engineered Installation Support Simplified Construction […]

GFRC Integration with Brick Veneer

Case Study: Architectural GFRC Cladding, Veneer, Trim, Columns, Wainscots, Balustrade | Custom Color and Finish for Desired Design Aesthetic […]

Design Options with Custom Shapes

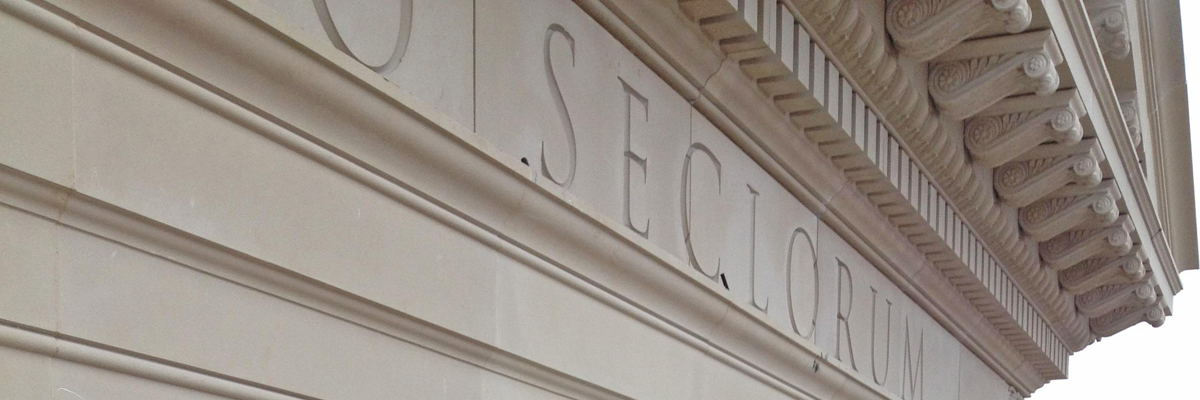

Jeffersonian Design using Custom Design Manufactured Stone | Old Parkland, Dallas, TX | Specially Designed Columns, Egg-n-Dart Rope Design, Large Dentils, Profile | Project Specific Engineering Design, Manufacturing, Sequencing, Delivery, Installation Support[…]

Project Execution, Design Support

Design review, custom fabrication, construction planning, installation, troubleshooting […]

GFRC Manufacturing Process: See Videos

See GFRC Manufacturing Steps | Learn from Series of Video Clips for Cornices used at SMU Sorority House Building Project […]

Match Any Custom Color: Examples

Manufactured Stone Veneer with Monolithic Stone Design Accent, Custom White Color | Project: Higher Education Complex | PBK Architects | Contractors: Tim Hughes, Dee Brown Inc […]

Product Materials Comparison Guide

AAS Project: The Westbrook – Sundance Square West – Ft Worth, TX | Art Deco Design using Cast Stone | Custom Mold Design | Architect: Bennett Benner Pettit, Inc[…]

Custom Architectural GFRC Columns

See Design, Engineering, Manufacturing of Custom Fabricated GFRC Columns At Mesa Precast Plant […]

Hampton Inn | GFRC for Design,Durability

AAS Case Study | GFRC Added High-End Design Elements, AND Provided More Durable, Robust Product Option […]

GFRC Veneer Installation - Video

Architectural GFRC Panels Veneer Adding Accent to Wood and Steel Elevation | Thin, Light Weight, Custom Color GFRC Panels at Gilbert Snooze Restaurant […]

Combine Stone Panels: Case Study

Combine Products with Seamless Look, Design Aesthetic | Opens up Design Options, Saves Cost, Simplifies Construction […]

Manufacturing Plant: Video Tour

Learn more about AAS Customer Project Process | Design and Estimation, Coordination, Custom Manufacturing, Computerized Color Lab, Installation Support […]

Architectural GFRC: White Paper

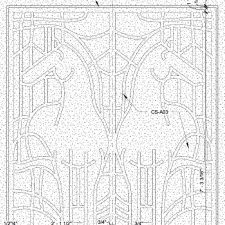

GFRC Art Panels for Art Deco Design Accent | GFRC Integrating Seamlessly with Brick Veneer

GFRC (Glass Fiber Reinforced Concrete): Product Downloads

Get Product Specifications – PDF File…

Get Product Specifications – Word File…

GFRC Advantage

- Unique potential to mold the stone panels in highly intricate shapes and complex design details.

- With unique materials technology coupled with pre-designed, pre-engineered built-in connections, the thin, lightweight (GFRC) concrete panels have a much better strength to weight ratio than other concrete products.

- The products can be manufactured with high precision and accuracy – exterior cladding, stone veneers, and facades can be created with flexibility in design options and ease of installation.

- GFRC panels can be easily integrated with brick veneer and other concrete products.

- The look and feel of the AAS GFRC panels can match other pre-manufactured stone products and natural stone products such as limestone. This enables options to combine different concrete or stone materials in a project with seamless aesthetic appeal – for example, use wet-precast concrete with embedded steel reinforcements for structural elements while using GFRC for higher elevation cornices and wall coping.