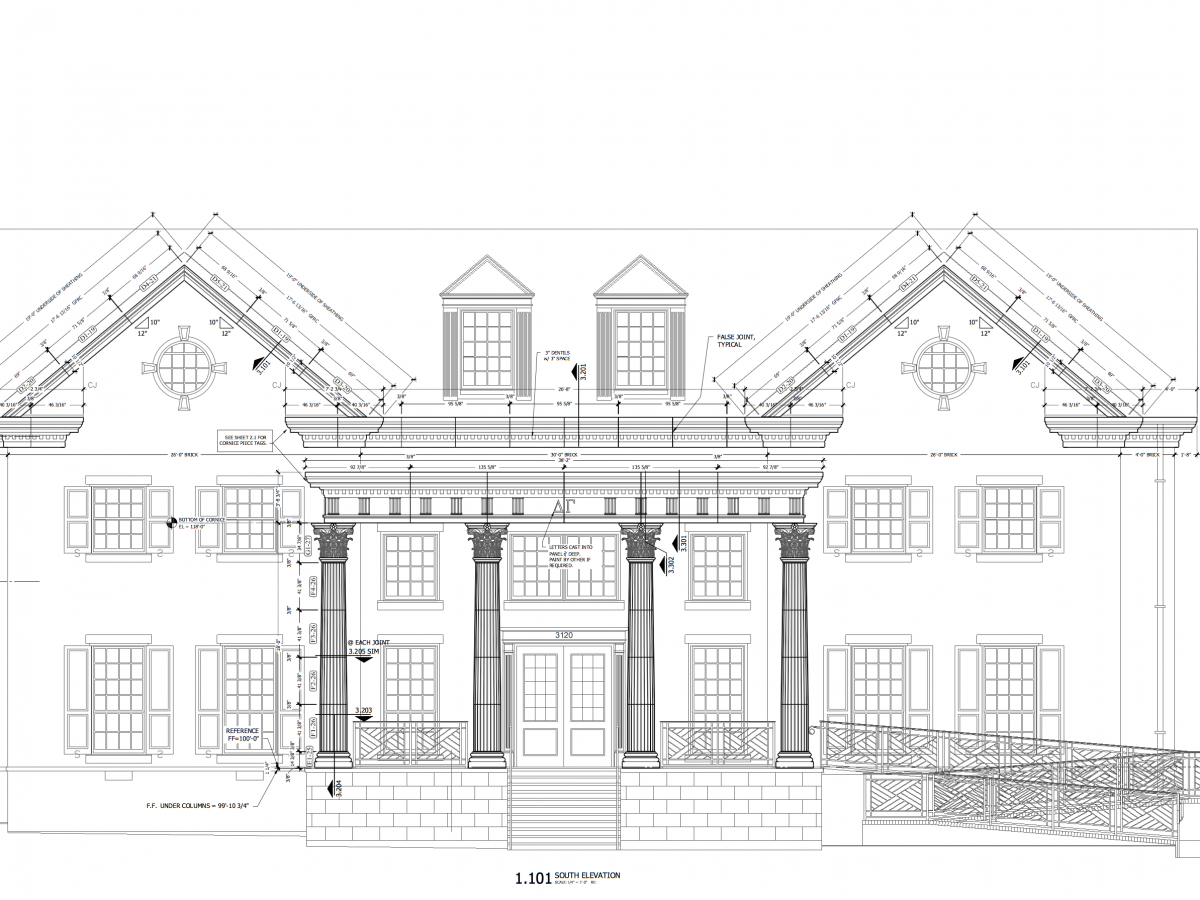

GFRC Panels Cladding for SMU Delta Gamma: Columns, Capitals, Cornices, Signage, Wall Coping, Trim

SMU (Southern Methodist University) Delta Gamma Sorority House is on the east side of the main campus of the university. A critical requirement for the project was to conform to a strict code of design compatibility for all buildings on the campus. The AAS team worked closely with the designer, general contractor, and mason to realize the design cost-effectively minimizing risk and delays.

Custom Design, Manufacturing of GFRC Products to Achieve Design Vision: Close Collaboration on all Phases of the Project

DESIGN ASSIST, CONSTRUCTION ASSIST

- Value Engineering – AAS engineering team suggested using architectural GFRC (glass fiber reinforced concrete) panels for this project after an in-depth review of the design requirements. The selection of GFRC panels minimized structural support requirements while providing design flexibility to realize required intricate design details.

- Design Assist – The AAS team reviewed design details for the project and provided feedback to confirm design feasibility. The AAS team collaborates with the design team using AutoCAD, Revit, or other BIM software products as required.

- Construction Assist – The design team provided installation guidelines, answered questions to detail the anchoring conditions for the GFRC panels.

GFRC PRODUCTS DESIGN, MANUFACTURING

- Color Matching – The AAS team took control sample and developed the custom batch mix for the GFRC panels to precisely match other buildings on the SMU campus.

- Custom Molds, Manufacturing – The CAD department took the architect’s design details and developed drawings. The structural support, installation anchors, connection details were pre-engineered during this phase.

- Products Consistency – Different product applications such as column covers and capitals, cornices, banding, signage, trim for window surrounds and entryway, etc. have consistently matching color and structural properties. AAS uses a fully automated batch plant along with the rigorous product quality assurance testing to achieve this on every customer project.

CONSTRUCTION, INSTALLATION SUPPORT

- Construction Planning – The different panels were manufactured, staged, and delivered with a thorough detailing of the installation sequence.

- Installation Support – The AAS project team explained installation details to the masonry contractor, enabling a smooth construction process.

Mason for the project: “This was our first project with GFRC. Installation was much simpler than any other cast stone project that we have done so far. GFRC is extremely easy to install.”

GFRC PRODUCTS: SEE MANUFACTURING IN WORKS

Custom Design GFRC Cornices

GFRC cornices with pre-engineered connections for simple, easy installation: see the manufacturing process for GFRC cornices in this VIDEO BLOG POST >>

Fluted Tapered GFRC Columns, Corinthian Capitals

Custom design fluted, tapered GFRC columns, and Corinthian capitals … VIDEO CLIPS show the manufacturing process for creating different components of the modular design >>

GFRC INSTALLATION, CONSTRUCTION SUPPORT FOR THE PROJECT

Pre-engineered built in connections simplified the installation empowering architect’s design process.

PROJECT IMAGES:

Architectural GFRC (Glass Fiber Reinforced Concrete)

- High strength to weight ratio

- Much simpler installation compared to other stone products

- Consistent product quality and finish, durability

- Unparalleled design freedom

GFRC Panels with Pre-engineered Built-in Connections Provide Design Flexibiliity and Simplify Construction | Video, Project Examples >>