The architectural GFRC (Glass Fiber Reinforced Concrete) presents a unique opportunity for architects and contractors.

The panels are only 3/4″ thick and yet are strong. This minimizes the structural support requirements. The panels can achieve the look and finish of other stone products. With the AAS technology and fabrication technique, the panels can be large in size when required with intricate shapes.

For renovating the Marriott Hotel in downtown Ft. Worth, the designers wanted to use GFRC panels to conform to existing building profile conditions. The AAS team worked closely with the architect and contractor to achieve panels with more than 20 ft. of length and highly complex angles. The connections to hang the panels were built-in during the engineering and manufacturing process, simplifying the installation.

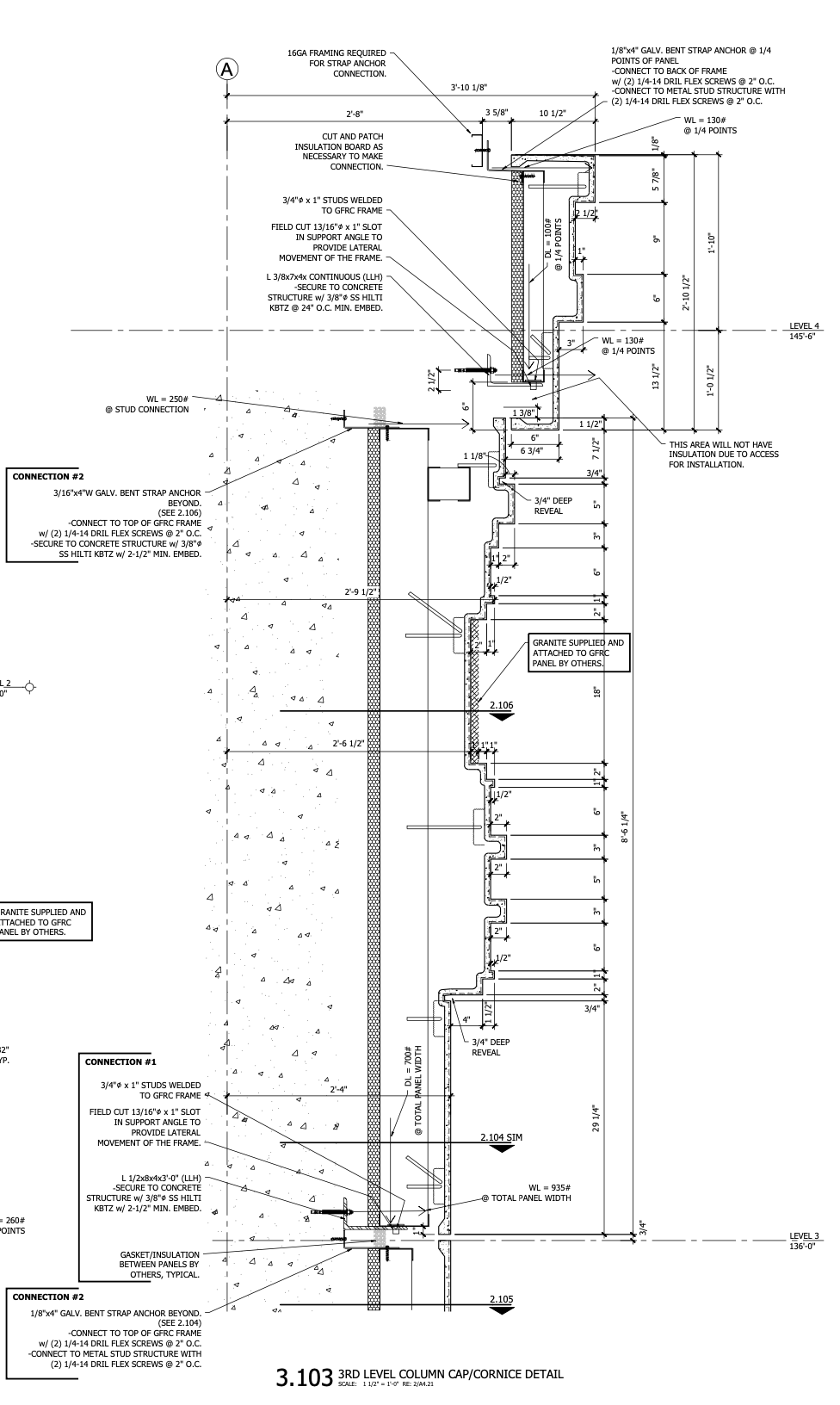

Images below show an example CAD drawing, a large panel with pre-engineered connections ready for shipment, and installation progress on the site.

CAD Drawing for One Panel

Coordination between a column cap and a cornice – Detailed engineering confirmed design feasibility and simplified installation process

Example: Custom-fabricated Large GFRC Panel

GFRC panel being Cast with Steel Frame Attachments

GFRC panel with Pre-engineered Connections Loaded for Shipping | More than 20 ft long architectural GFRC

Installation Site: Marriott Hotel, Ft. Worth, TX

Detailed Engineering for Seamless Coordination of Columns and Cornices

Marriott Hotel – GFRC Cladding