SMU Simmons Hall: Design, Manufacturing, Project Coordination

AAS Project: SMU Simmons Hall | Cast Stone, GFRC, Precast Concrete | 2016 CSI Awards for Manufacturing Excellence, Design Excellence | DOWNLOAD AND LEARN MORE >>

The HAROLD CLARK SIMMONS HALL is a classic building on the campus of Southern Methodist University (SMU) in Dallas, Texas. It is an academic building with classroom and student labs for various departments.

The structure is approximately 40,000 square feet.

The architectural stone cladding and design accent kept the building consistent with the adjacent buildings on the campus.

The project won 2016 awards from the CSI (Cast Stone Institute) in the categories of Design Excellence, and also Manufacturing Excellence.

The project won the 2017 Golden Trowel Award in the category of educational buildings.

DOWNLOAD PROJECT INFO >>

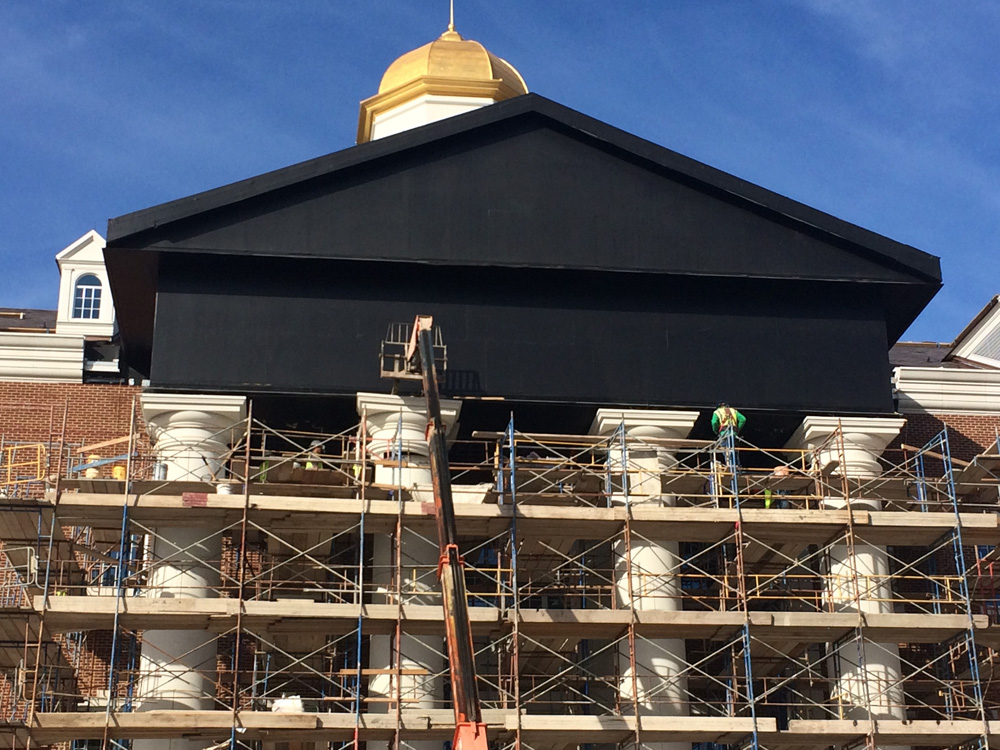

Large Size Cast Stone Columns

The key feature of this structure is the oversize cast stone columns. Each column in the front elevation of the building has the height of all four floors of the building. The diameter for these columns is five to six feet.

AAS team designed custom molds using detailed CAD drawings and then precisely cut them using CNC machining capabilities. The process used not only the AAS technology but also the design craftsmanship of the project team members.

The computerized batch plant provided consistency in color and the structural properties of the manufactured stone.

SMU Simmons Hall | Cast Stone, GFRC, Precast Concrete | Large Size Columns Designed using Custom Molds | Balusters, Balustrade System Design | DOWNLOAD AND LEARN MORE >>

Balustrade System Design

The AAS team designed an elaborate balustrade system that blended seamlessly with the rest of the architectural stone cladding application. AAS custom-fabricated stone for the entire project using a dry vibrant-tamped casting process.

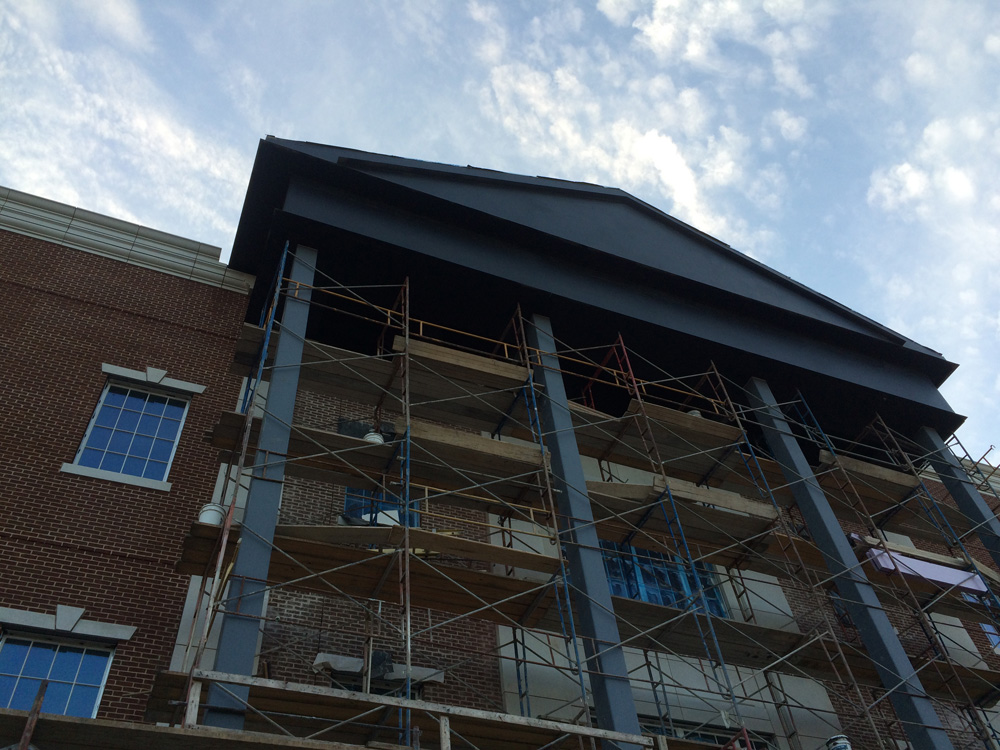

Architectural Stone at Higher Elevation

Architectural stone cladding design for SMU Simmons Hall has manufactured stone at a higher elevation as well.

Vibrant-tamp dry cast stone is much lighter in weight compared to wet cast stone. That is an advantage with the AAS technology and manufacturing techniques.

AAS project team can work closely with customers for value engineering, combining GFRC (Glass Fiber Reinforced Concrete) panels for applications like this. AAS can match the color and finish while combining wet-cast stone, dry-cast stone, and also GFRC stone.

Detailed Engineering, Precise Manufacturing, Construction Support, Project Coordination

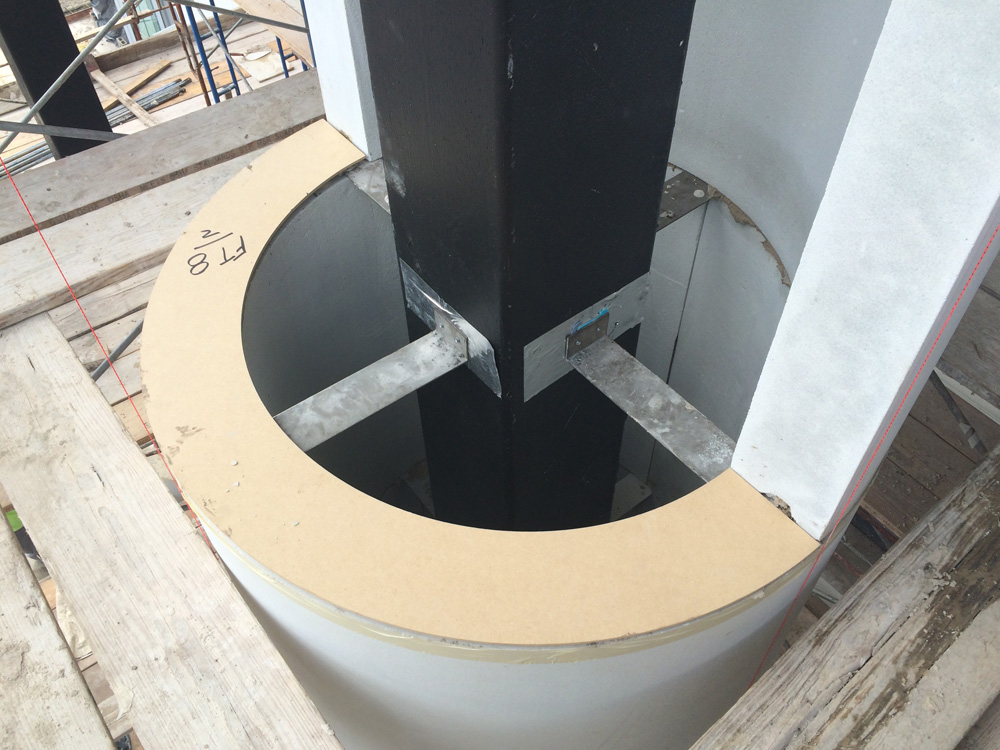

The side entry columns required detailed engineering and production planning. These columns were inset into a radius wall, meaning that the columns were not symmetrical—a unique design and manufacturing challenges. Each piece required custom curvature on the inside and tapered cylindrical shaping on the outside.

Project-specific custom fabrication: The cylindrical base of the columns and the pieces attached from both sides have a custom shape, allowing the installers to hang the cast stone in place without carving or retrofitting.

AAS provided a detailed layout or setting plan that showed how all the pieces joined together for the construction.

The manufacturing and delivery schedule planned delivery releases in sync with onsite construction milestones. AAS has a very well thought out system of labeling every pallet; that simplifies the installation of the cast stone pieces.

Installing Cornices at High Elevation: Troubleshooting, Conforming to As Built Conditions

The entry porticoes had assemblies that tied into the cornice on the main building. Because the structural steel was slightly off, the transition cornice on the portico didn’t align properly with the main building cornice.

The AAS project manager worked closely with the mason and developed full-scale templates. The project team then coordinated this with the CAD department and the form shop to ensure that the pieces matched onsite field conditions.

The AAS team designed and fabricated the improvised cast stone with four days of turn around.

Project:

HAROLD CLARK SIMMONS HALL, Southern Methodist University (SMU)

Architect:

Perkins and Will

General Contractor:

Vaughn Construction

Masonry Contractor:

Wilks Masonry

Product:

Architectural Cast Stone