Color Options

AAS believes that color choice is an important reason to use manufactured stone products such as cast stone, architectural precast, Architectural GFRC and GFRG. The architectural community desires color harmony on any project.

There are many factors to consider while selecting color and texture for masonry products.

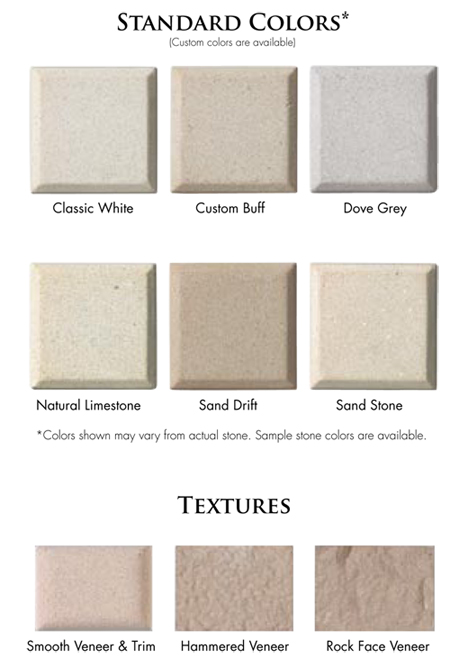

AAS Standard Colors

- AAS standard colors are those that have been chosen more often than other colors for many years. All of these colors are muted and are similar to the colors of limestone.

- As a general rule, our products are accentuated when there is contrast with other materials on a building. Reddish brick and our classic white product is a favorite among designers. If a monochromatic effect is desired, our products often look better in darker shades. The darker colors often give the effect that the structure is larger and bolder. These projects usually require custom colors.

- If there is a product that our products must be matched with, send a control sample of the other product to the AAS color lab. We will be able to match that color.

- Our products are colored with through an integral computerized color system. This means that the color is part of the mix design and is part of all raw material components eliminating fading.

- Cast stone, architectural precast, and GFRC all are made with natural raw materials. The largest color variable is the use of sand and aggregate material. AAS goes to great trouble to buy from the same sources. With that said, the reason our products are an architect’s choice, is that they vary from piece to piece of stone, just like limestone and other natural products vary. The variation gives a natural stone appearance.

- Light is a significant contributor to color. Always review product choices at different times of the day; and on both a sunny and cloudy day.

Texture Options

- The majority of our products are considered a smooth finish. The closest analogy to this finish is “beach sand”. There is a very refined texture to the surface of the product. Again, this texture is very natural in appearance.

- There are other textures and finishes that can be achieved with AAS products. Other surfaces include hammered finish, rock-face finish, and many others. To achieve these surfaces, a liner is used in the production process that reflects the surface desired.

- There are other surfaces often known in the design world as distressed, chipped, or Old World to give the effect of age. AAS has implemented these textures as well on wide range of projects.

CASE STUDY: See a number of project examples where AAS team customized colors to match designer’s vision and desired aesthetic appeal.