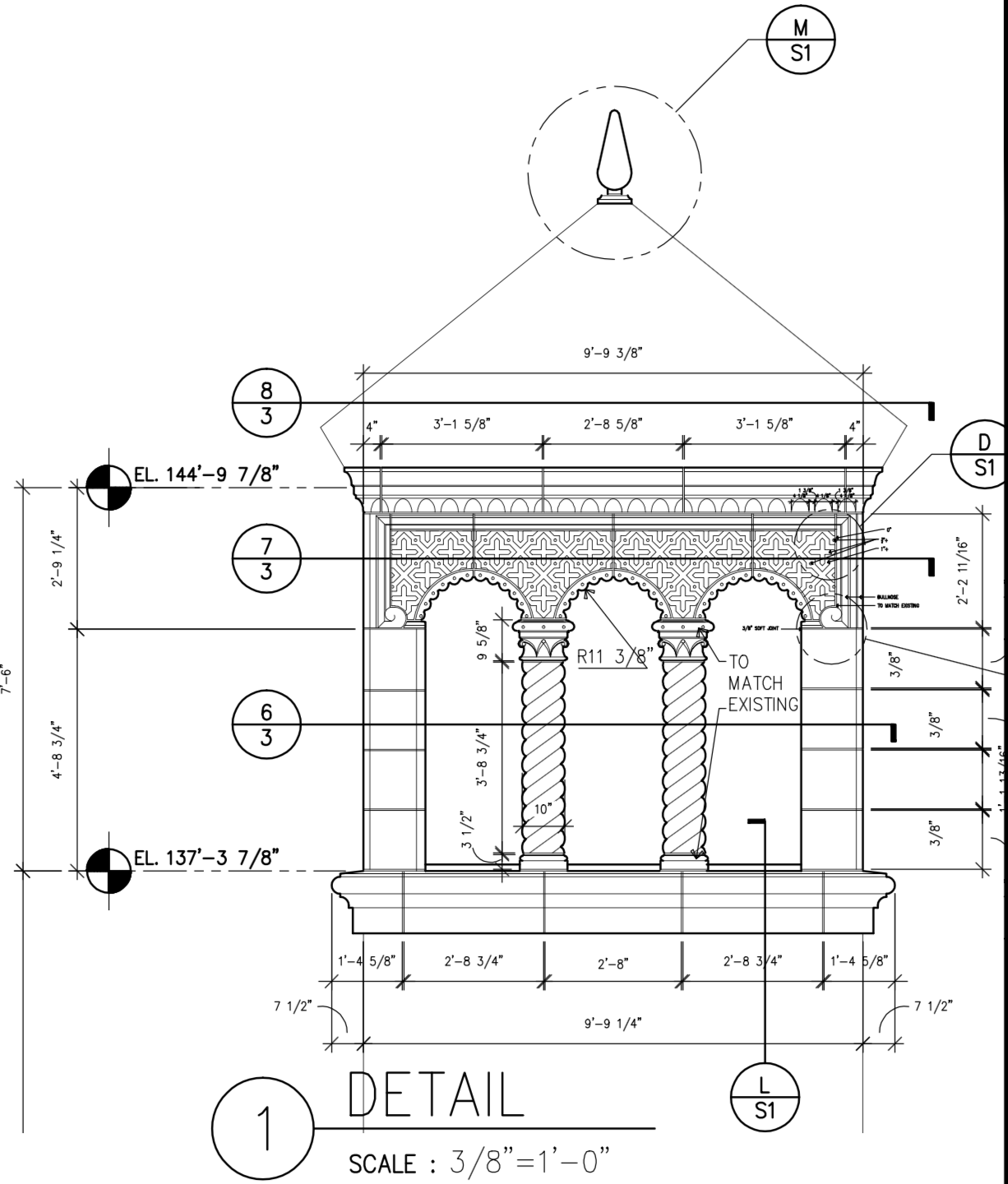

Balusters are used for design accent with commercial as well as residential buildings for centuries.

AAS GFRC manufacturing technique is able to cast balusters in one piece without any seams. This enables superior design aesthetic while also simplifying the installation of the balusters at the construction site.

The fabrication method uses mold for each side or half of the baluster. The inside of the molds is sprayed with a thin layer of the GFRC mix for the desired finish.

Mold for for casting balusters

Spraying outer layer of GFRC mix for desired look and finish of balusters

Inspection, hand packing using brush for uniform surface finish quality

Inspection, hand packing using brush for uniform surface finish quality

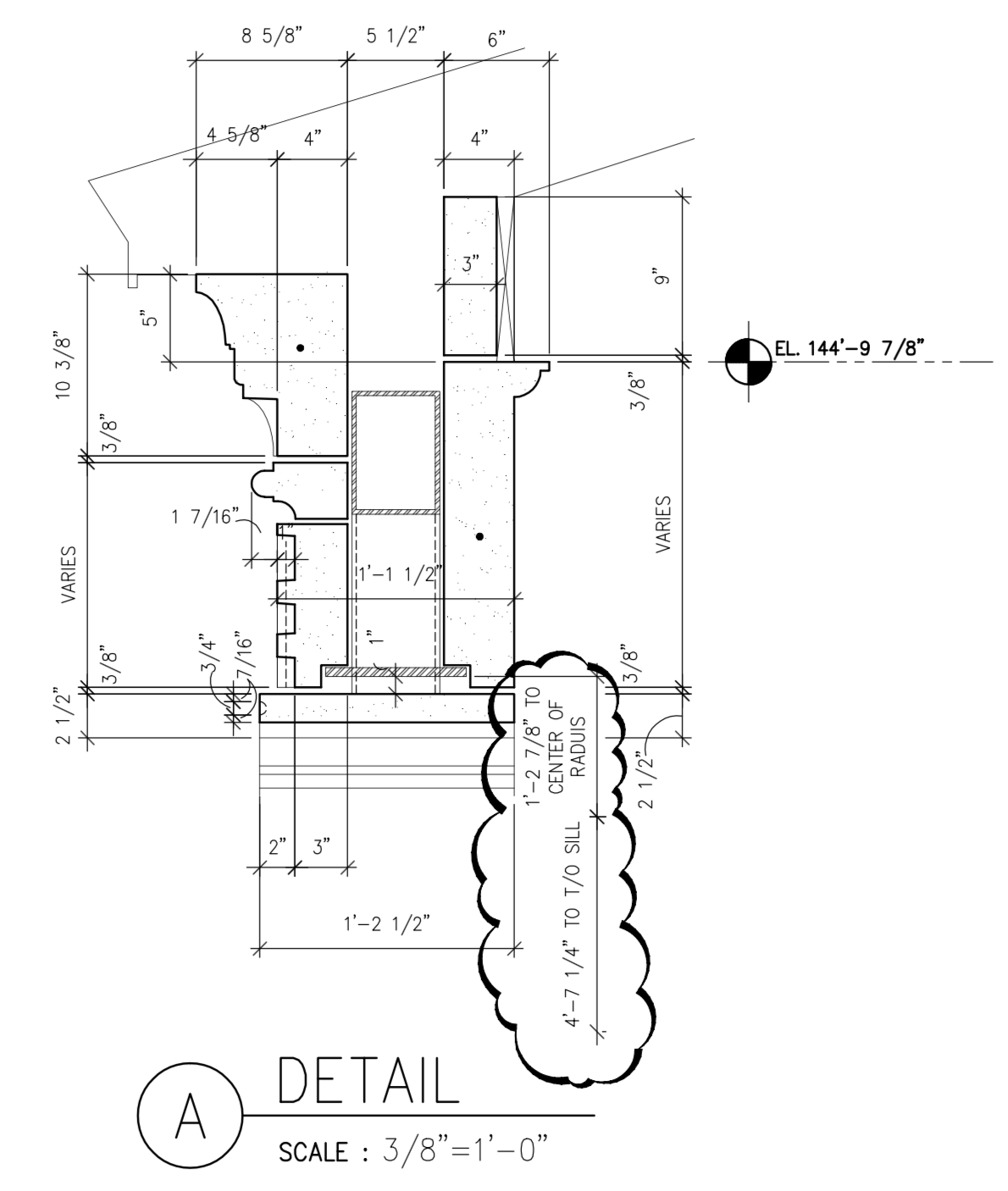

After that the two mold pieces are held together to fill in the GFRC admixture inside. The center of the cylindrical space has 2” wide PVC, so that way the finished GFRC baluster has hollow core in the middle.

GFRC balusters cast in one piece

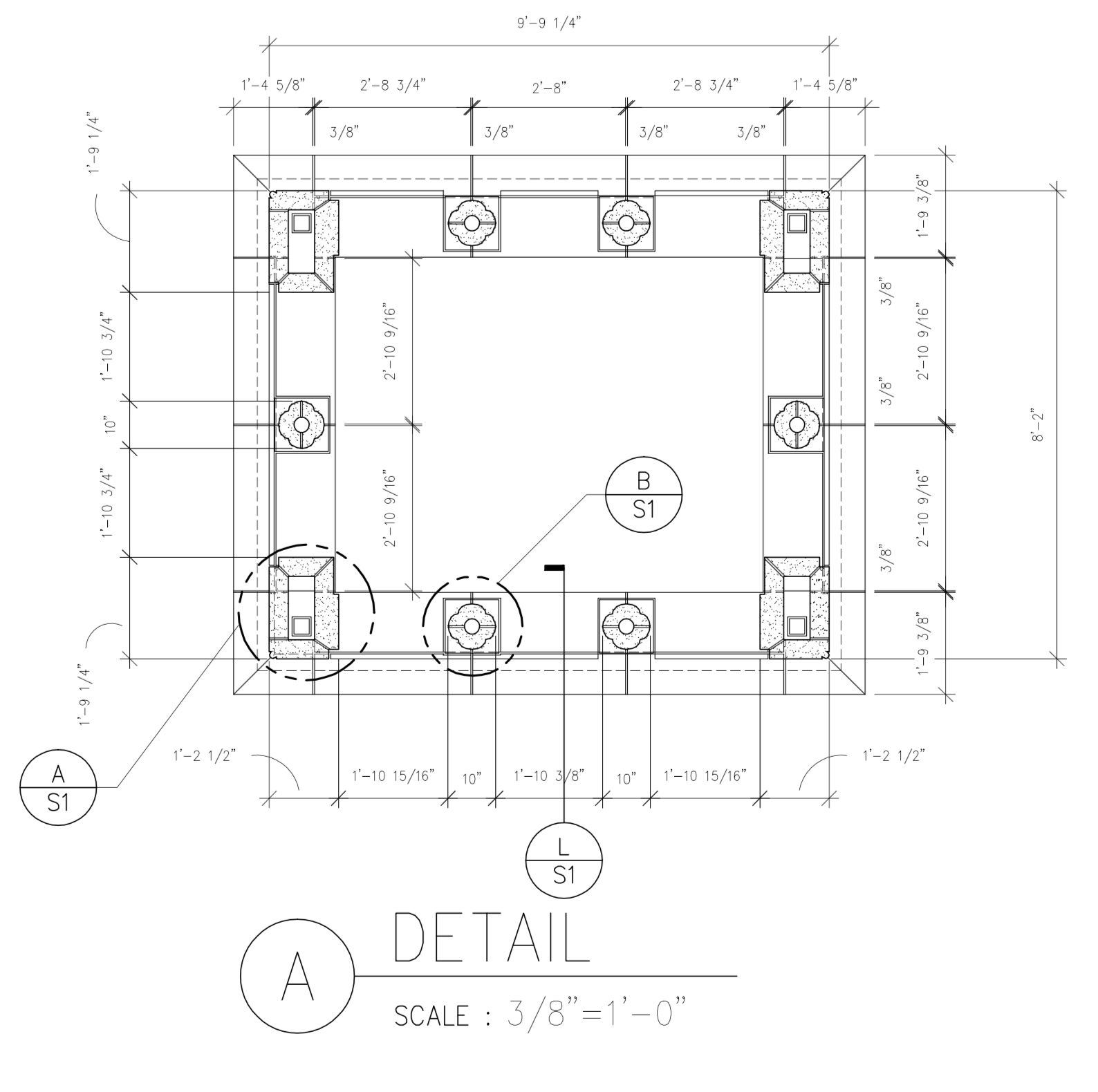

In a typical installation, threaded rod is passed through the hollow core in the middle. The rod is attached to the steel channel for securing balusters in place. The AAS team is able to custom design the handrail for the balustrade system so that it has groove from inside to conceal the steel channel inside.

The AAS team is able to make project specific molds as required for the custom size and shape of the balusters.

AAS is able to match color of any control sample provided by the customers.

The AAS team is able to guide customers with selection of the product material, as well as the most appropriate installation details that would achieve the desired design intent.