Products: Cast Stone, Architectural GFRC & Precast, GFRG

Advanced Architectural Stone provides architectural design solutions using four different types of stone materials –

- Cast Stone

- Architectural Precast

- Architectural GFRC(Glass Fiber Reinforced Concrete)

- GFRG (Glass Fiber Reinforced Gypsum

Select, Combine Product Materials

The AAS team is able to guide customers with selecting the right product(s) for a project.

AAS technology is able to match the colors and finish for a seamless experience while combining different materials on a project.

See the product comparison guide to learn more while selecting the product(s) for a project. Or, contact us and our support team would be happy to answer any questions you might have about the product selection.

Unique Manufacturing Capabilities, Production Knowledge

While many firms can make products having a cement basis, AAS is able to use its production knowledge to design and manufacture products for architecturally driven projects. AAS team is able to create any custom color and desired finish for products.

AAS project team is able to provide design consultation as needed. AAS has the most sophisticated system of incorporating the customer’s ideas into a finished product.

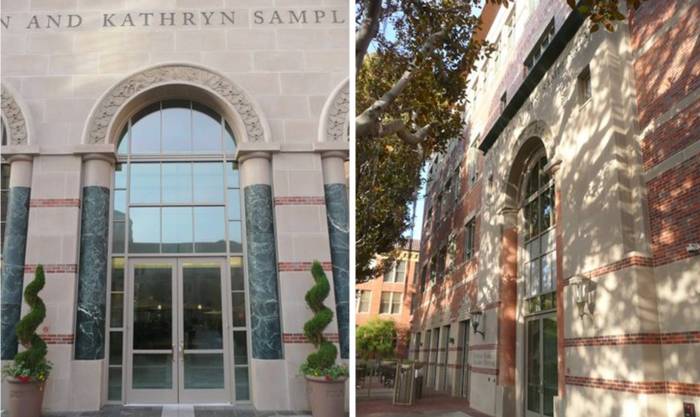

Many of our products have a traditional design, with the use of classic columns, entrance ways, window surrounds, and other ornamentation. However, AAS also has the ability to design products that work well with contemporary structures, those using significant amounts of glass and steel, and almost any combination of other building materials.

Custom Molds with Precision, Design Flexibility

Mold or design capabilities separate a satisfactory producer from a truly exceptional supplier such as Advanced Architectural Stone.

AAS has both ends of the spectrum in design –

- Technology provides dimensional exactness, and

- Artisans provide beauty, craftsmanship

Very few companies are skilled at incorporating both into mold production, yet Advanced Architectural Stone does both exceptionally well.

Products Consistency, Beauty – Batch Plant

The quality of raw materials used in the finished product makes a large difference between an exceptional architectural piece with beauty similar to limestone and a piece that is functional, but without the natural beauty achievable with Advanced Architectural Stone.

AAS product designs provide the looks found in natural products with the added strength of an engineered product.

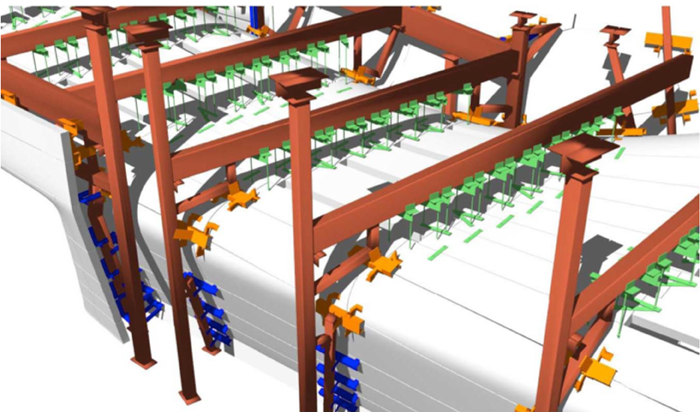

With a fully automated, computerized batch plant, AAS has technology set up to track and monitor materials composition throughout the life cycle of every project.

Advanced Architectural Stone |AAS – Formerly Advanced Cast Stone | Cast Stone, Architectural Precast ,GFRC | Cooks Children Hospital Project

Cast Stone

Cast Stone is produced by a process known as dry-cast or vibrant-tamp production method. Cast stone is a highly refined white Portland concrete material manufactured to simulate natural cut stone. The production method uses a process to carefully grade aggregates. To further enhance its natural stone look, the process also uses much less water than other precast stone products. Advanced Architectural Stone has a computer driven color system that can produce almost any color for a project. The company has six standard colors and an infinite ability to match the color of other building materials.

Cast stone pieces are determined by the geometry of the stone; often piece sizes are smaller than those available in architectural precast. Cast stone is not a structural building product. Cast stone pieces are custom fabricated for each project.

LA Museum & Sports Hall of Fame | Cast Stone | Trahan Architects | VCC | Masonry Arts | See CASE STUDY …

Methodist State University – Caruth Hall | Cast Stone | Hahnfeld Hoffer Stanford Architects | Dee Brown Masonry

Architectural Precast Concrete

Architectural precast is produced by a process known as a wet pour method. It is distinguished from ordinary precast because it is often made from white Portland cement and greater care is given to the extra steps used in the process often known as finishing. Finishing can include acid washing or sandblasting to remove a film that often occurs during the manufacturing process, filling holes or other imperfections on the surface of the product after it is removed from molds, and finishing the edges of the product – much like a baker would decorate a cake.

There are properties that architectural precast has that cast stone does not. For example, pieces of precast can be made much larger and can have structural support properties, if so desired. The process itself is a more costly production process and therefore the material will be more expensive than cast stone. In general, the product is not as refined or natural-looking as cast stone, but can be enhanced to achieve a very compatible finish to cast stone if that specification is requested.

AAS has over 30 years of experience in delivering quality products and design solutions using architectural precast.

Architectural GFRC (Glass Fiber Reinforced Concrete)

Visually, architectural GFRC looks the same as either cast stone or architectural precast, since the surface of this product is designed in the same manner. The underside and strength of GFRC actually comes from specially produced nylon that looks like feathers. These nylon feathers provide structural and flex strength to GFRC. This product is more expensive than cast stone and architectural precast, but product cost is often offset with other savings.

GFRC Advantage

GFRC (Glass Fiber Reinforced Concrete) offers a number of significant advantages while designing and installing projects.

- Architectural GFRC is much lighter; the weight is usually 50% lighter than cast stone or precast.is Where both cast stone and architectural precast are used as product materials, the product is completely filled with cast material. Where as, GFRC is hollow, somewhat like a donut, making the product lighter. GFRC is also known as light weight concrete for that reason.

- Much higher strength to weight ratio compared to other stone products. This makes it very well suited to higher elevation applications.

- The use of less structural building core of either wood or steel thus saving the cost of these materials and labor to install the additional structural material.

- Less labor in the installation process since lighter material are usually larger pieces and easier to work attach, thereby saving on labor costs.

- Often on large jobs, a less experienced and cheaper labor pool is qualified to install this material.

- GFRC is able to achieve the same aesthetic appeal as cast stone, or architectural precast product materials. This is achieved through compatible mix design.

AAS (Formerly ACS) | Gilbert Christian High school | Product: Architectural GFRC (Light Weight Concrete) | Architect: L. Smith – H & S International LLC. | Contractor: A. R. Mays

Glass Fiber Reinforced Gypsum (GFRG)

GFRG is a compound of high density gypsum and glass fiber reinforcement. This product is for applications where the product is not exposed to the exterior of a structure. It is light weight and therefore has significant advantages over decorative applications of plaster and other molded interior products. Advanced Architectural Stone is a premier supplier GFRG (Glass Fiber Reinforced Gypsum). GFRG is made using designed molds in the AAS manufacturing plant and delivered to the job site in a finished state ready for installation.

The advantages of receiving a completed product at the job site are significant compared to job site construction:

- Factory quality control in an ideal production environment is always preferred over the working conditions in a building under construction.

- Exact architectural detailing can be achieved in factory production.

- Economies of production of more than one piece are achievable in a plant environment.

- Since the product is much lighter in weight less structure and structural support is necessary to achieve the same look.